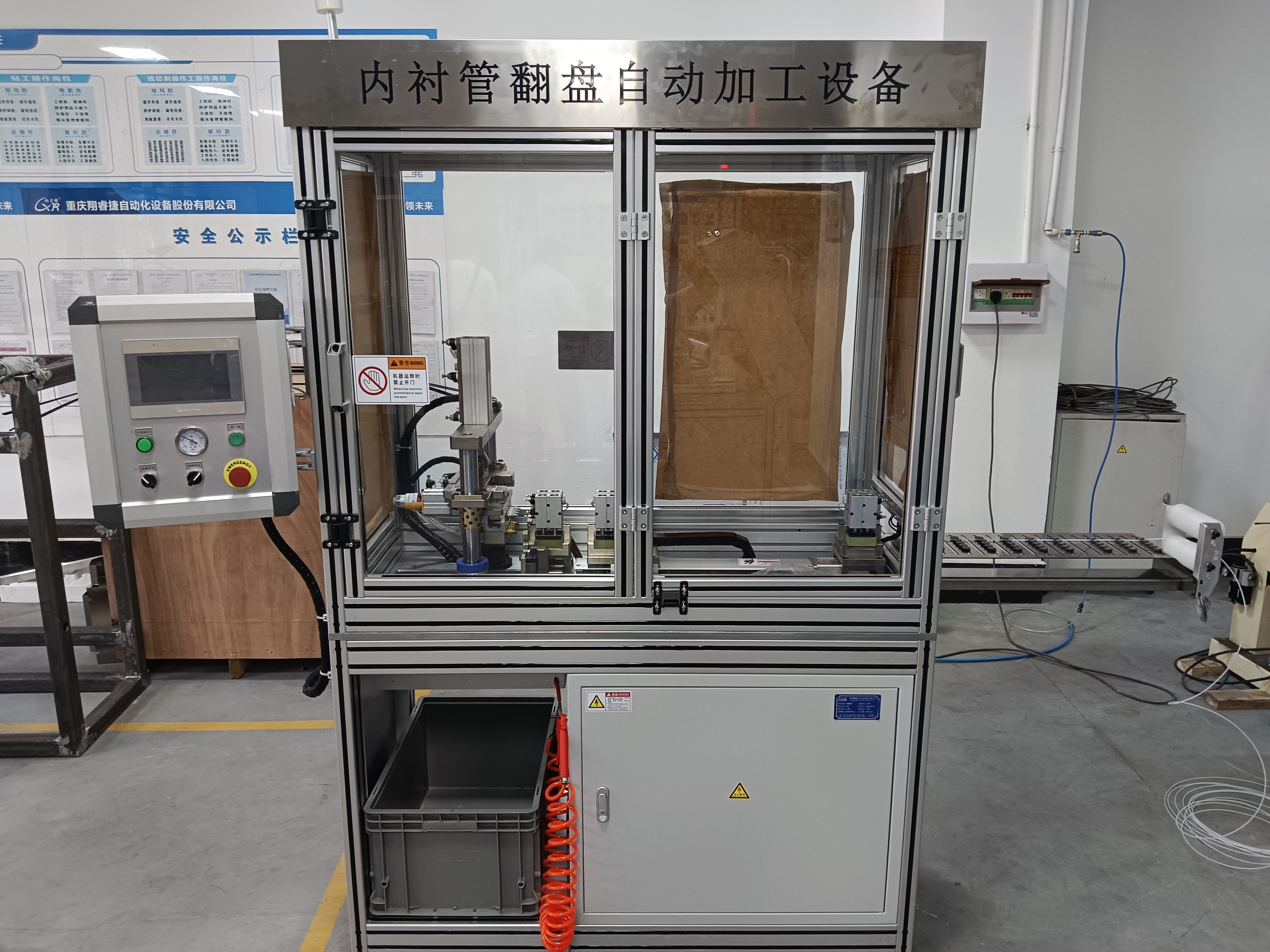

玻璃升降器流水线

本生产线满足左前、左后、右前、右后的玻璃升降器装配要求(产品和工艺)

This production line meets the assembly requirements of the glass lifters (products and processes) at left front, left back, right front and right back.

关键词:

玻璃升降器流水线

所属分类:

详情描述

本生产线满足左前、左后、右前、右后的玻璃升降器装配要求(产品和工艺)。

2. 每个工位采用人工手动喂料,人工出料,工位与工位之间采用不锈钢滑槽或旋转料架交替输送。

3.生产线采用单件流动原则,工位与工位之间按1-10件缓存设计。

4.生产线总共设计3个工位,每个工位基本平衡,工位时间节拍为40S/件,每天8小时产量约为700件。

5. 每个工位对易错装,漏装,和反装的零件,适当应用防错技术,对其进行防错监控。

6. 每个工序完成,人工对相应的装配特性(错漏装,是否到位,运转性能等)进行自检,并作相应标记 。

7.检测设备满足检测项目为:上升时间/速度、上升电流、堵转电流、堵转力、弹簧弹出量、传动掣高低差检测;检测数据通过工控机进行分析,通过条码打印机打印条码。

8.终检设置外观检测台:对易错漏装的零件,外观件,产品性能等项目人工再次确认。

9.按流程进行不合格品控制,质量管理,工艺管理。

10.适当应用设备管理,安全,人机工程,快速换模换线,外观等技术。

This production line can meet the assembly requirements of glass lifters (products and processes) of left front, left back, right front and right back.

2. Each station adopts manual feeding and manual discharging. Stainless steel chute or rotating material rack is used for alternating conveying between stations.

3. The production line adopts the principle of single piece flow, and the buffer design between stations is 1-10 pieces.

4. The production line is designed with 3 stations in total, and each station is basically balanced. The time of each station is 40S/ piece, and the output is about 700 pieces in 8 hours per day.

5. Each station shall properly apply the error-proof technology to the parts that are easy to be misinstalled, misinstalled, and backloaded, and shall conduct error-proof monitoring.

6. After each process is completed, the corresponding assembly characteristics (wrong and missing installation, whether in place, operation performance, etc.) shall be manually self-checked and marked accordingly.

7. The test equipment can meet the test items: rising time/speed, rising current, blocking and turning current, blocking and turning force, spring ejector volume, transmission switch difference detection;The test data is analyzed by ipc and printed by barcode printer.

8. Set up appearance testing platform for final inspection: manually confirm the parts, appearance parts and product performance that are easy to be installed by mistake.

9. Control non-conforming products, quality management and process management according to the process.

10. Appropriate application of equipment management, safety, ergonomics, quick change of mold and wire, appearance and other technologies.

相关设备