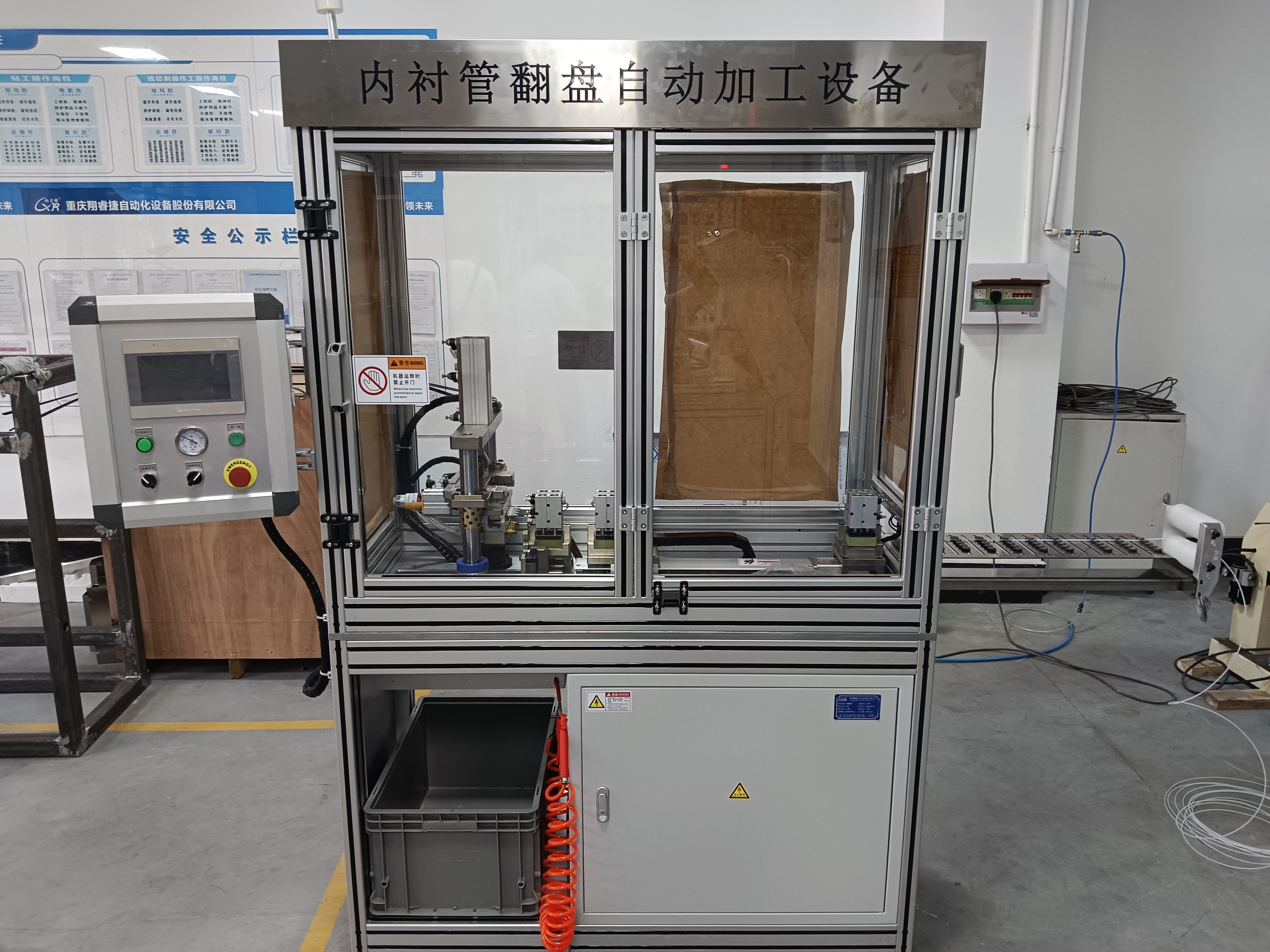

落线铆小夹头自动加工设备

关键词:

所属分类:

详情描述

1、设备集成了钢丝绳原材料匹配、穿弹簧、下线、小夹头铆压、拉脱力检测、尺寸检测、产品合格品与不合格品分选、产品数量批量储存、合格品打印标签等动作。与传统的分离式工艺相比,具有保证产品质量、提高生产效率、及减少人员配置的优点;

2、设备工位移动机构采用整体同步行进,保证了产品级进精度和可靠性;

1. The equipment integrates the actions of wire rope raw material matching, spring piercing, looping, small collet riveting, puller testing, dimension testing, product qualified and unqualified product sorting, product quantity and batch storage, qualified product printing label and so on.Compared with the traditional separation process, it has the advantages of ensuring product quality, improving production efficiency, and reducing personnel allocation.

2. The station moving mechanism of the equipment adopts the overall synchronous motion, which ensures the product's progressive accuracy and reliability;

3. The equipment adopts the man-machine control interface, realizes the parameterized visual control, and facilitates the production staff to change the corresponding parameters according to the actual production requirements. The product detection data has the function of background storage, and the equipment failure can be indicated;

4. The electrical components and electrical control components of the equipment all adopt well-known brands at home and abroad to ensure the operation accuracy and stability of the equipment;

5. Reasonable debugging of equipment, design of maintenance door, better realize debugging and maintenance of equipment in later period;

相关设备