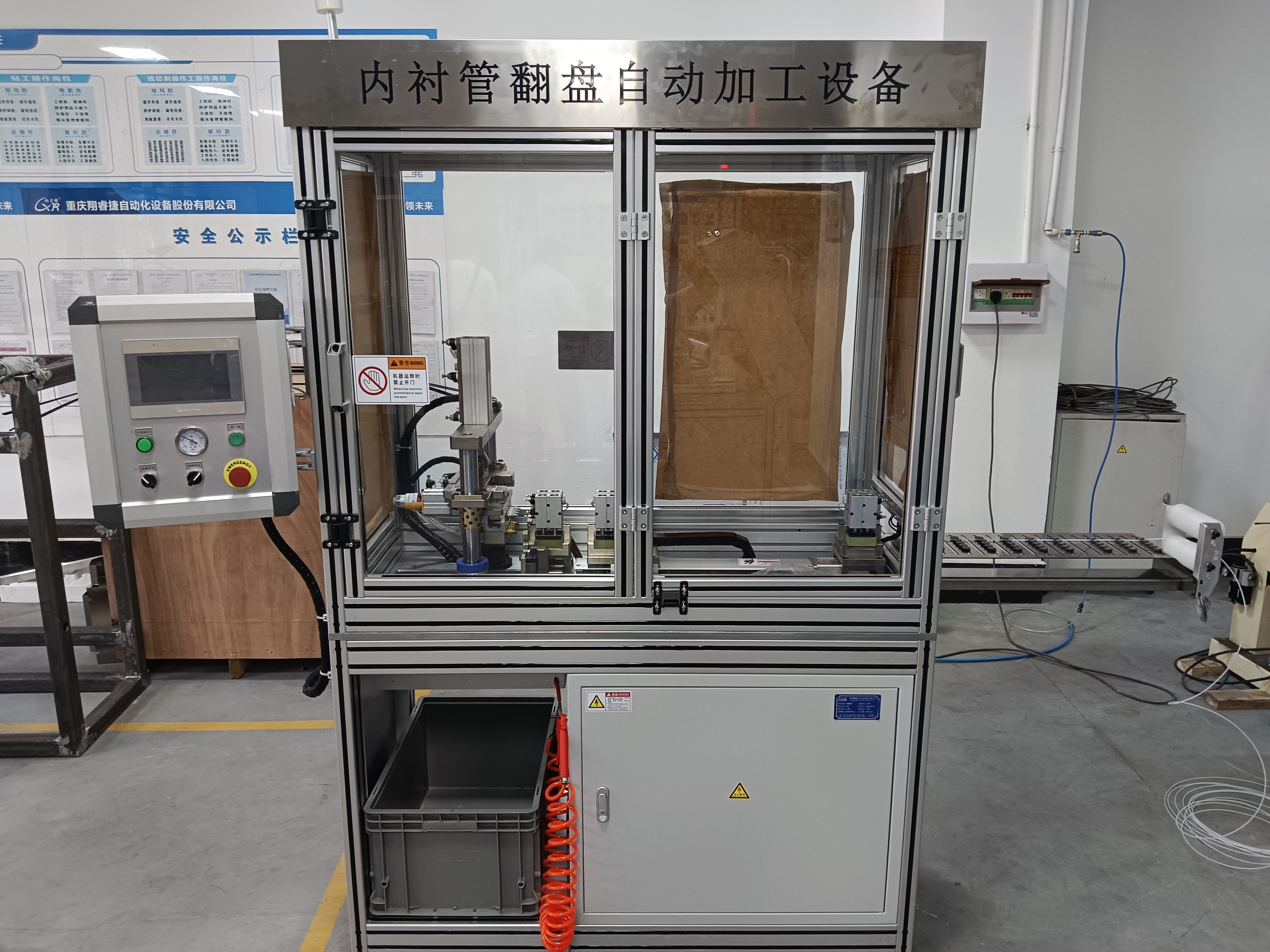

拉索螺杆铆压综合一体机

1)电源220V、50Hz,气源0.5-0.7Mpa;

2)适用于套管类型:本设备适用于φ5-φ6-φ7弹簧软管或直丝管,保证管子直线度;

3)适用于钢丝绳类型:本设备适用于φ1.5-1*19、φ1.8-1*19、φ2.0-1*19、φ2.5-1*19钢丝绳;

4)加工产品尺寸范围:压力管长度范围900mm-1900mm、A+B长度范围42mm-242mm,精度±1mm;产品极限总长度:942mm-2142mm(不包含螺杆接头长度尺寸);

5)带防尘套产品加工要求:需满足A+B长度尺寸大于(42mm加上防尘套自然状态下长度尺寸);

6)螺杆零件要求:螺杆外形整体通圆无方盘,规格M5、M6,长度65-68±1mm,螺杆内孔倒角60度,倒角圆润无飞边快口,内孔与外径保证同心度小于0.1mm;

7)压铆力:15T,压铆总行程:100mm,增压行程:15mm;

8)精切机构剪切力:5000N;

9)拉脱力检测参数:气压0.3Mpa出力1300N±50N,气压0.6Mpa出力2700±50N,拉力传感器最大量程0-500Kg,精度0.3%;

10)A+B行程检测参数:检测力50N±10N,拉力传感器最大量程0-50Kg,精度0.3%,位移传感器量程0-100mm,精度0.3%,分辨率0.02mm,检测气缸行程0-60mm;

11)产品分选容量100套;批次分选数量自由可调;

12)产品数据储存100万组,可导出;

13)产品报废率不大于1%,因产品零件质量问题不计入产品报废率;

14)设备动作1个循环周期时间不大于5s,不包含人工装件时间;

15)设备更换产品工装调整时间不大于15分钟,按熟练工人测算;1) power supply 220V, 50Hz, air source 0.5-0.7mpa;

2) applicable to the type of casing: this device is applicable to 5-6-7 spring hose or straight wire tube, ensuring the straightness of the pipe;

3) suitable for wire rope type: this equipment is suitable for the 19, phi phi 1.5 1 * 1.8 1 * 19, 19, phi phi 2.0 1 * 2.5 1 * 19 wire rope;

4) size range of processed products: pressure tube length range 900mm-1900mm, A+B length range 42mm-242mm, accuracy ±1mm;Total product limit length: 942mm-2142mm (not including screw joint length and size);

5) processing requirements for products with dust jacket: A+B length shall be met if the size is larger than (42mm plus the length of dust jacket in the natural state);

6) screw parts requirements: screw overall shape through a round non-square plate, M5, M6, length of 65-68±1mm, screw hole chamfering 60 degrees, chamfering round no flash flash, inner hole and outer diameter to ensure the concentricity of less than 0.1mm;

7) riveting force: 15T, total riveting stroke: 100mm, pressurized stroke: 15mm;

8) shear force of fine cutting mechanism: 5000N;

9) tensile force detection parameters: air pressure 0.3mpa output 1300N±50N, air pressure 0.6mpa output 2700±50N, maximum range of tension sensor 0-500kg, accuracy 0.3%;

10)A+B stroke detection parameters: detection force 50N±10N, maximum range of tension sensor 0-50kg, accuracy 0.3%, displacement sensor range 0-100mm, accuracy 0.3%, resolution 0.02mm, cylinder stroke 0-60mm;

11) product sorting capacity of 100 sets;Batch sorting quantity is freely adjustable;

12) 1 million sets of product data can be stored and exported;

13) the scrap rate of products shall be no more than 1%, and shall not be included in the scrap rate due to quality problems of product parts;

14) the time of one cycle of equipment action should be no more than 5s, excluding the time of human tooling;

15) the adjustment time of equipment replacement and tooling shall be no more than 15 minutes, calculated by skilled workers;

关键词:

拉索螺杆铆压综合一体机

所属分类:

详情描述

设备集成了精切、铆压、拉脱力检测、有效行程检测、产品合格品与不合格品分选、产品数量批量储存等动作。与传统的分离式工艺相比,本设备有保证产品质量、提高生产效率、及减少人员配置的优点;设备工位移动机构采用整体同步行进,保证了产品级进精度和可靠性,设备采用人机控制界面,实现参数化可视控制,方便生产员工根据实际生产需求更改相应参数,产品检测数据具有后台储存功能,设备故障可显示根据理论时间节拍分析,生产节拍预估为:6s/件,8小时班产量:4800件设备使用电器元器件、电气控制元件均采用国内外知名品牌,保证设备运行精度及稳定性;设备合理的调试、维护门的设计,更好的实现后期设备的调试和维护;

The equipment is integrated with precision cutting, riveting, pulling force testing, effective stroke testing, product qualification and non-qualification product sorting, product quantity batch storage and other actions.Compared with the traditional separation process, this equipment has the advantages of ensuring product quality, improving production efficiency and reducing personnel allocation.Equipment location mobile mechanism adopts whole synchronization, ensure the product level into the accuracy and reliability of equipment is controlled by the man-machine interface, realize the parametric visual control, convenient to change the corresponding parameter according to actual production demand, production staff product testing data with a backend storage function, equipment failure can be displayed according to the theory of time rhythm analysis, produce the beat forecasts for: 6 s/a, 8 hours of class output: 4800 pieces of equipment used electrical components, electrical control components all use well-known brands at home and abroad, to ensure the precision and stability of equipment operation.Equipment reasonable debugging, maintenance door design, better realize the late equipment debugging and maintenance;

相关设备