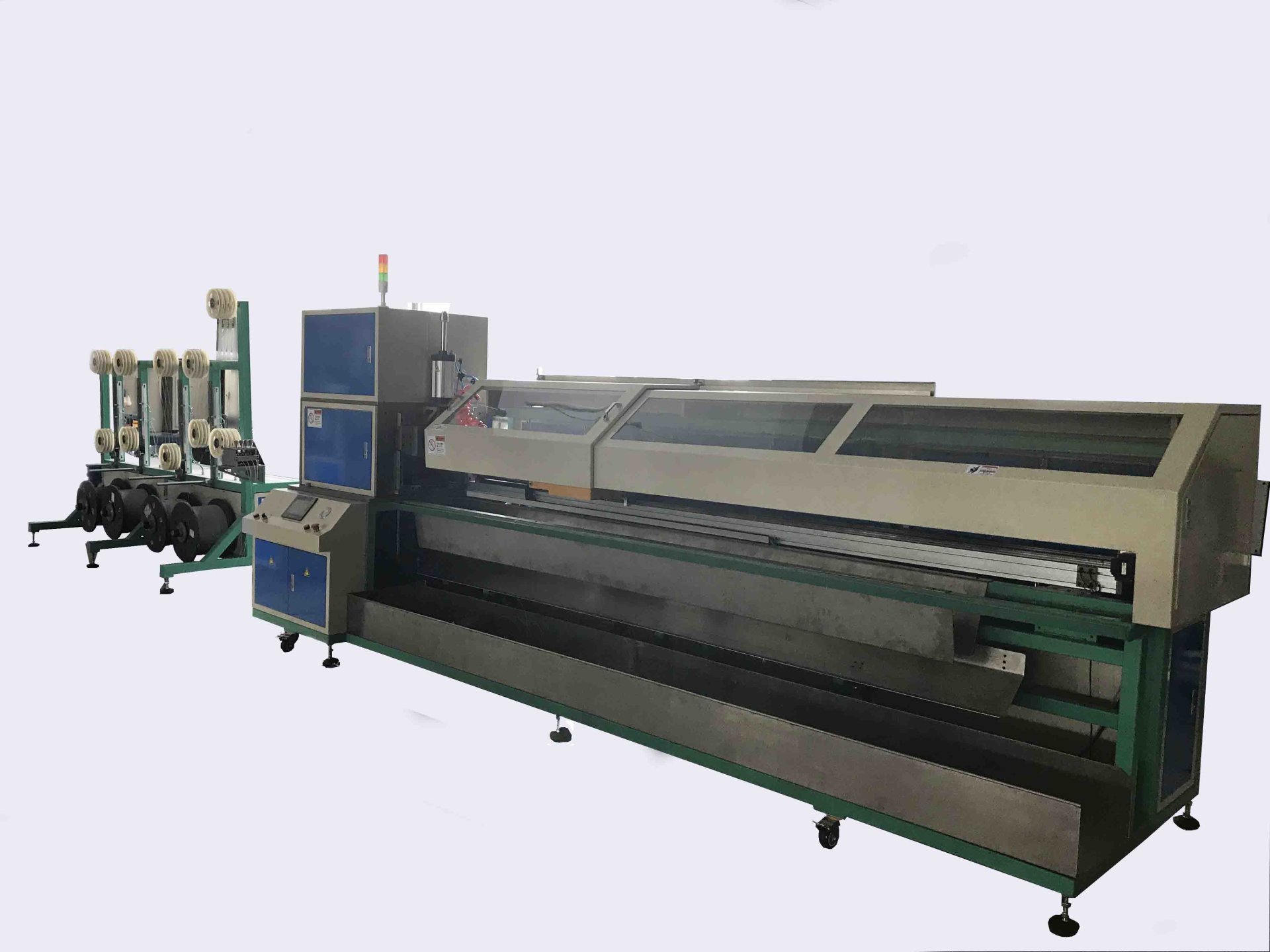

全自动四根熔断打花机

本项目设备工位移动机构采用整体同步行进,保证产品级进精度和可靠性;采用人机控制界面,实现参数化可视控制,便于实时更改相应参数,加设产品检测数据后台储存功能,便于提示观察,与传统的分离式工艺相比,本设备有保证产品质量、提高生产效率、及减少人员配置的优点,更好的实现后期设备的调试和维护。

The mobile mechanism of the equipment station in this project adopts the whole synchronous movement to ensure the product grade accuracy and reliability.Parametric visual control is realized by using the man-machine interface, control, convenient for real-time changes corresponding parameters, including product testing data backend storage function, facilitate prompt observation, compared with the traditional separate technique, this equipment is guaranteed product quality, improve production efficiency, and reduce staffing, the advantages of better implementation of the late equipment debugging and maintenance.

关键词:

全自动四根熔断打花机

参数化可视控制

所属分类:

详情描述

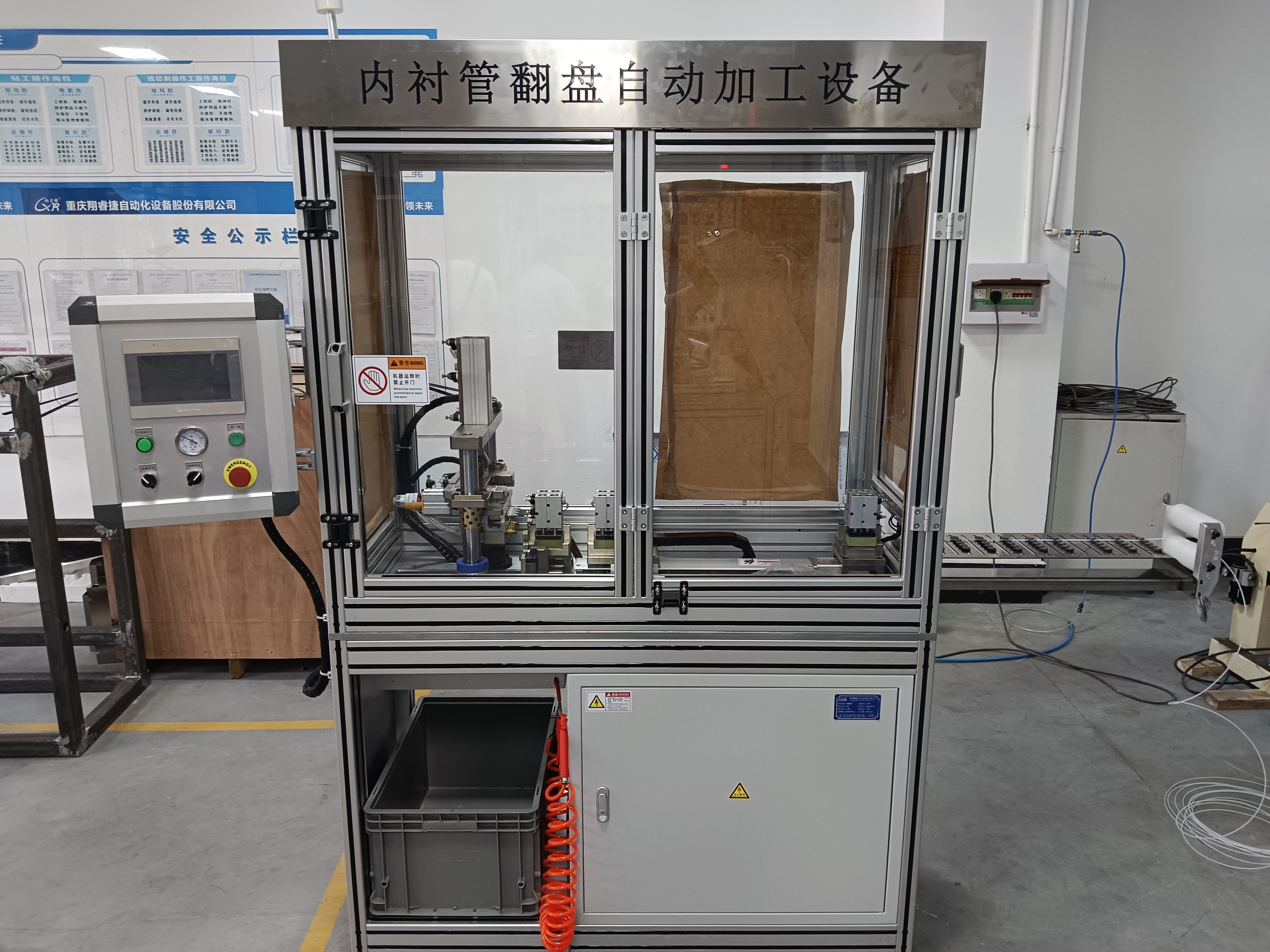

本设备具有4条钢丝绳同时送料-同时自动熔断-同时打花-同时记忆指定尺寸与数量-同时自动卸料一体完成,提高设备的利用效率,提高产品精度,提高生产效率,减少人工成本,广广泛用于汽车门锁线,升降器拉索,摩托车驻车拉索等行业

This equipment has four wire feed at the same time - and at the same time with automatic fuse - flower - and memory specified size and quantity - automatic unloading completed at the same time, improve equipment efficiency, improve product accuracy, improve production efficiency and reduce labor costs, wide line is widely used in automobile door lock, levelers, lasso motorcycle parking cable and other industries

相关设备