外壳切断剥皮倒角机

关键词:

所属分类:

详情描述

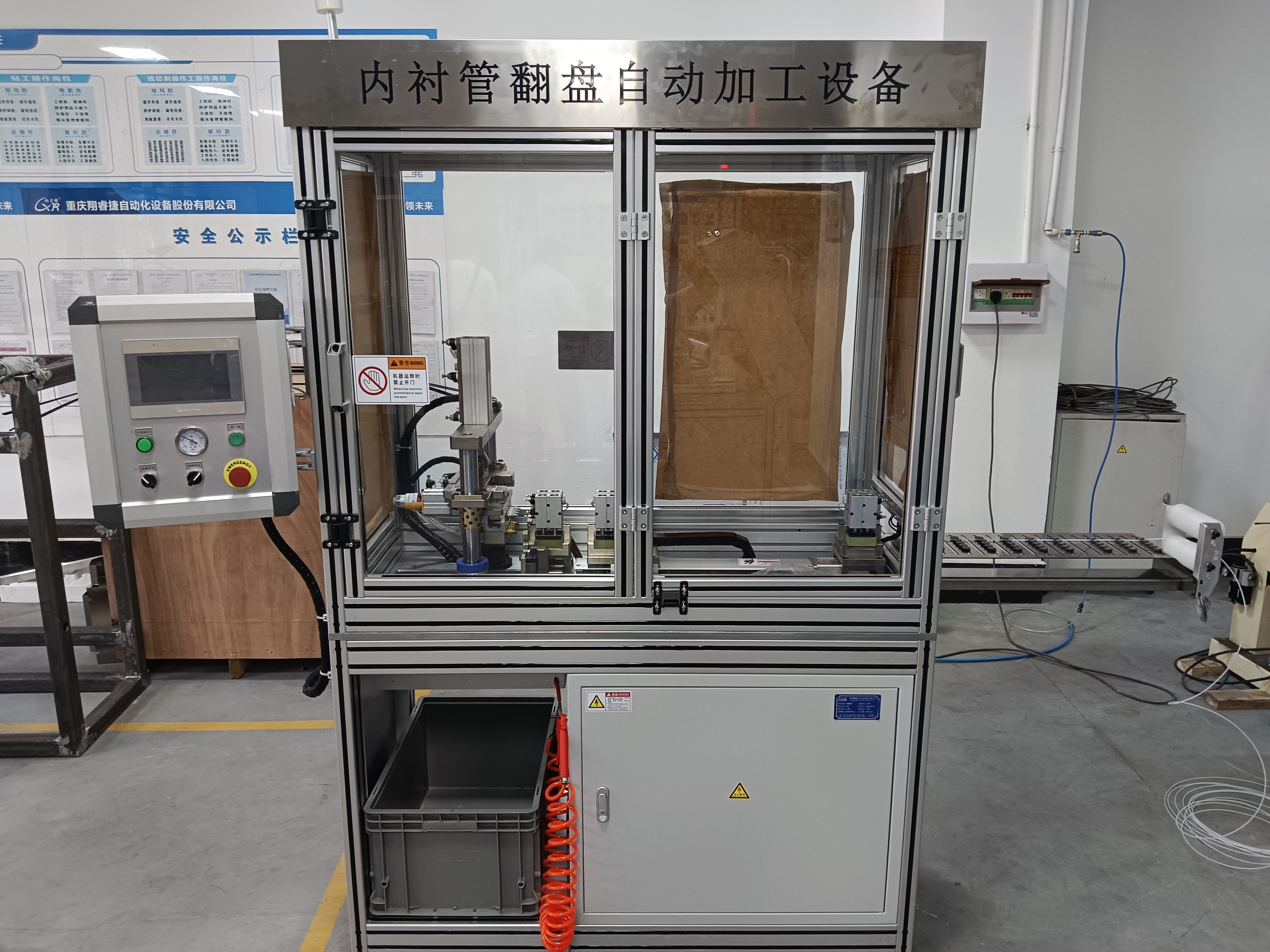

设备介绍

设备组成:多头自动钻孔工作台由机体、定位工装、伺服进给装置、冷却系统、人机界面及可编程控制器等组成。

工作原理:将标准产品的数据通过人机界面输入并保存,将待打孔的工件放置到定位工装指定位置,按下双手启动按钮,设备开始工装打孔完成后自动返回原点,超出行程或出现信号检测失败等系统发出警报提示。

设备特征:本设备采用多重互锁安全检测模式,实时安全报警信息;通过配置的高精确度传感器和智能化的可编控制器及伺服运动机构进行多头同时进给装置,具有速度快、故障率低、性能稳定、使用寿命长等特点,适用于多孔零件同时打孔作业。

Equipment introduction

Equipment composition: Multi-head automatic drilling table is composed of body, positioning equipment, servo feed device, cooling system, man-machine interface and programmable controller.

Working principle: input and save the data of the standard product through the human-machine interface, place the workpiece to be punched to the designated position of the positioning fixture, press the start button with both hands, and the device will automatically return to the origin after the completion of the tooling drilling, and the system will give an alarm when the stroke is exceeded or signal detection fails.

Device features: The device adopts multiple interlock security detection mode and real-time security alarm information;Through the configuration of high precision sensors and intelligent programmable controller and servo motion mechanism for multi-head simultaneous feed device, with fast speed, low failure rate, stable performance, long service life and other characteristics, suitable for multi-hole parts at the same time drilling operations.

相关设备